Frame rail replacement doesn't need to compromise environmental sustainability. Auto body shops adopting eco-friendly practices, such as using recycled materials, water-based coatings, and proper disposal methods, can minimize their carbon footprint while providing high-quality repairs. These green approaches, including paintless dent repair and energy-efficient equipment, reduce waste, chemical use, and energy consumption. Businesses prioritizing sustainability in frame rail replacement can differentiate themselves, appeal to eco-conscious consumers, and contribute to a lower industry carbon footprint.

In the realm of automotive restoration, understanding the environmental considerations behind frame rail replacement is paramount. This process, crucial for structural integrity, carries significant ecological implications. The article delves into the fundamentals of frame rail replacement and its environmental impact, exploring sustainable materials and practices that minimize ecological damage. Additionally, it guides readers on long-term care and maintenance strategies to reduce the automotive repair sector’s environmental footprint, offering a holistic approach to this vital process.

- Understanding Frame Rail Replacement: The Basics and Environmental Impact

- Sustainable Materials and Practices for Frame Rail Restoration

- Long-Term Care and Maintenance: Reducing Environmental Footprint in Automotive Repairs

Understanding Frame Rail Replacement: The Basics and Environmental Impact

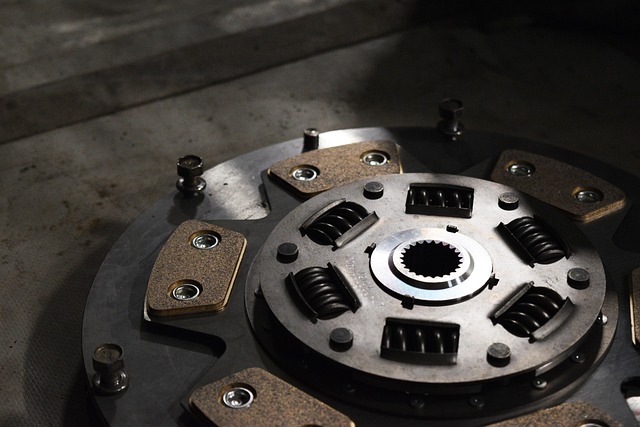

Frame rail replacement is a critical process in automotive repair that involves replacing or restructuring the structural framework of a vehicle. This procedure is essential for ensuring the safety and integrity of the vehicle, particularly after damage from accidents or corrosion. The frame rails are the backbone of the car’s structure, connecting various components like the suspension, wheels, and body panels. Understanding this process is crucial for both automotive professionals and vehicle owners to comprehend its environmental implications.

The environmental impact of frame rail replacement cannot be overlooked. Traditional methods often involve extensive welding, cutting, and fabrication, leading to significant amounts of waste and emissions. The use of heavy metals in manufacturing and the potential release of toxic substances during disposal are also concerns. However, many auto body shops and auto collision centers have adopted more sustainable practices. These include utilizing recycled materials, implementing efficient painting processes like auto painting with water-based coatings, and promoting proper recycling and disposal of automotive parts. By embracing these eco-friendly approaches, the industry is moving towards minimizing its carbon footprint while ensuring high-quality frame rail replacements.

Sustainable Materials and Practices for Frame Rail Restoration

When undertaking frame rail replacement, sustainability should be a key consideration for both collision repair centers and vehicle body shops. Opting for eco-friendly materials is an essential step in minimizing the environmental impact of the restoration process. For example, using recycled steel or aluminum can significantly reduce carbon emissions associated with production compared to traditional metals. Additionally, these sustainable alternatives often have a lower energy requirement during processing, contributing to a greener approach to frame rail replacement.

Incorporating green practices throughout the project is equally vital. This includes methods such as paintless dent repair techniques that avoid the use of harsh chemicals and reduce waste. By adopting innovative technologies and materials, collision repair centers can offer more environmentally conscious services while ensuring top-notch vehicle restoration.

Long-Term Care and Maintenance: Reducing Environmental Footprint in Automotive Repairs

In the realm of automotive repairs, particularly when undertaking a frame rail replacement, long-term care and maintenance play a crucial role in minimizing a vehicle’s environmental footprint. A car body shop that prioritizes sustainability can significantly reduce waste and energy consumption associated with bumper repair and other auto body services. This involves adopting eco-friendly practices such as recycling metal parts, properly disposing of hazardous materials, and utilizing energy-efficient equipment during the frame rail replacement process. By implementing these measures, a shop not only contributes to a cleaner environment but also ensures the longevity of the vehicle, thereby deferring the need for future repairs and reducing overall environmental impact.

Moreover, regular maintenance schedules can help identify potential issues early on, preventing major repairs that consume more resources. This proactive approach, coupled with using environmentally friendly materials where possible, can substantially decrease the carbon footprint of a car body shop. In light of these considerations, businesses offering frame rail replacement services have an opportunity to stand out by embracing sustainability, thereby appealing to eco-conscious consumers and contributing to a greener automotive industry.

Frame rail replacement, though essential for automotive repairs, can significantly impact the environment. However, with a shift towards sustainable materials and practices, as discussed in this article, the ecological footprint of such processes can be substantially reduced. By adopting long-term care and maintenance strategies, the automotive industry can contribute to a greener future while ensuring the structural integrity of vehicles. These environmental considerations are not just beneficial for nature but also ensure the longevity and efficiency of vehicles, making frame rail replacement a more sustainable and responsible endeavor.